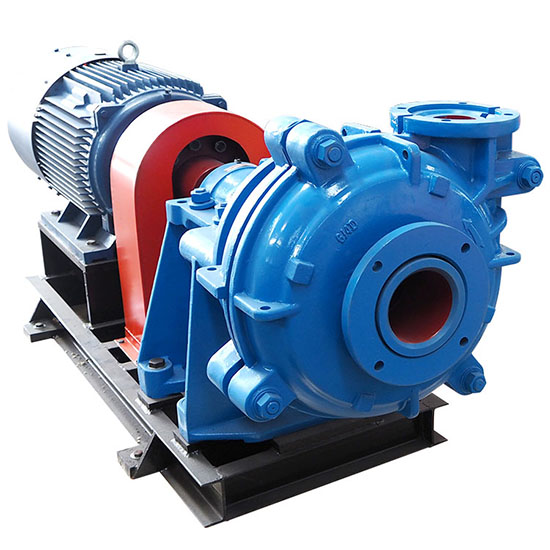

Horizontal Slurry Pump

Horizontal Slurry Pump

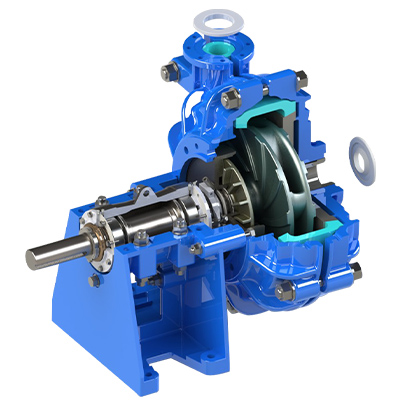

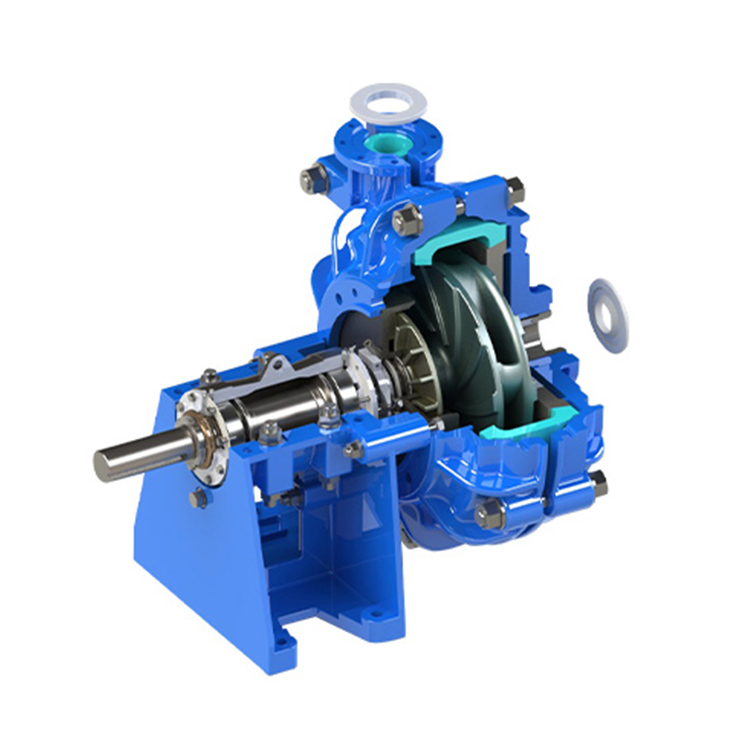

MAH series pumps are heavy-duty horizontal slurry pumps designed to handle the transfer of abrasive and high-density slurries in mining and heavy industry. MAH pumps feature a rugged cast iron construction with replaceable wear liners available in 27% chrome white iron, rubber or urethane to suit a wide range of applications, slurry types, and consistencies. All MAH slurry pumps are designed to be interchangeable with the most common slurry pump footprints used by the mining industry. MAH pumps are manufactured using the highest quality materials to ensure reliability and extended service life in heavy-duty applications.

Design Features

- Outlet: 32-350mm

- Flow rate: 10.8-6500m³/h

- Head: up to 125m

- Max. Power: up to 600kw

- Impeller diameter: 152-965mm

- No. of vane: 5

- Material: 27% were resistant Chrome

- Max. particle size: 14-104mm

A horizontal slurry pump is a type of pump designed specifically for handling slurries, which are mixtures of solid particles and liquids. These pumps are commonly used in various industries, such as mining, mineral processing, coal preparation, power generation, and others where the transfer of abrasive and/or corrosive slurries is required. The design of horizontal slurry pumps allows for efficient handling of heavy and abrasive materials.

1.Design and Orientation:

Horizontal Shaft: The horizontal orientation of the pump allows for easy installation and maintenance. The pump typically consists of a horizontal shaft, casing, and impeller.

2.Centrifugal Force:

Impeller Action: The impeller, which is a rotating component of the pump, imparts centrifugal force to the slurry. This force propels the mixture radially outward, creating the flow necessary for transportation.

3.Wear Resistance:

Material Selection: To combat the abrasive nature of slurries, horizontal slurry pumps are constructed using wear-resistant materials. High-chrome alloys and other durable materials are often used for the impeller, casing, and other critical components.

4.Interchangeable Parts:

Ease of Maintenance: The design of horizontal slurry pumps often includes interchangeable parts. This feature facilitates maintenance and repairs, reducing downtime in industrial processes.

5.Sealing Options:

Gland Packing or Mechanical Seals: Various sealing options are available to prevent leakage. Gland packing and mechanical seals are commonly used to ensure a secure seal and prevent contamination of the surrounding environment.

6.Various Configurations:

Application-Specific Designs: Horizontal slurry pumps come in different configurations to suit specific applications. Single-stage pumps are suitable for less demanding tasks, while multi-stage pumps may be used for higher pressure requirements. End-suction and split-case designs offer further options based on application needs.

7.Flow Rates and Head:

Versatility: Horizontal slurry pumps are designed to handle a wide range of flow rates and head conditions. This versatility makes them suitable for diverse applications where pumping requirements can vary.

8.Application-Specific Considerations:

Handling Abrasives: The robust design of these pumps is tailored to handle abrasive and high-density slurries commonly found in industries such as mining, mineral processing, and power generation.

9.Efficiency:

Optimized Performance: Maintaining pump efficiency is crucial in slurry applications. Manufacturers focus on optimizing the pump design to operate efficiently under challenging conditions, ensuring cost-effective and reliable performance.

Horizontal slurry pumps play a vital role in industries where the efficient and reliable transport of abrasive slurries is essential. The specific design features and materials used can vary among manufacturers, so it's important to consider the unique requirements of each application when selecting a horizontal slurry pump. Regular maintenance, proper monitoring, and adherence to recommended operating parameters are key to maximizing the lifespan and efficiency of these pumps in challenging environments.

Milestone's MAH series of horizontal slurry pumps stand at the forefront of technology, representing a significant leap in design and performance. With a keen focus on user feedback and leveraging the latest advancements in fluid mechanics, mechanical engineering, and computer software design, Milestone has engineered a series that sets new standards in the mining industry.

Crafted with meticulous attention to detail, the slurry pumps embodies a single-stage, single-suction, centrifugal design, elevating it above conventional counterparts. Its adaptability is underscored by a diverse range of outlet diameters, encompassing 1inch, 1.5inch, 2inch, 3inch, 4inch, 6inch, 8inch, 10inch, 12inch, 14inch, and beyond. Each pump specification offers a nuanced selection of impeller diameters, finely calibrated to meet specific head requirements, thereby ensuring optimal performance across an extensive spectrum of applications and operating conditions.

Innovative in both hydraulic and structural design, the MAH series sludge pump boasts flow passage parts meticulously fashioned from a proprietary, abrasion-resistant, high-chromium wear-resistant alloy cast iron. This material not only bestows the pumps with commendable efficiency but also imparts attributes of energy conservation, protracted service life, structural lightweightness, judicious design, operational reliability, minimal vibration, subdued noise levels, and streamlined maintenance protocols.

In a proactive response to the diverse demands of clientele, Milestone introduces a bespoke series of slurry pumps, intricately tailored to cater to specific applications and exacting specifications. This bespoke approach underscores Milestone's steadfast commitment to providing tailored solutions, addressing the unique challenges faced by clients within the dynamic landscape of the mining industry.

Beyond the confines of product innovation, Milestone distinguishes itself as a vanguard of reliability and energy efficiency in slurry pump manufacturing. The company's prowess in quality manufacturing is vividly evident in the expansive range of products within the MAH series, affording users a comprehensive selection that seamlessly aligns with a myriad of performance criteria and working conditions. The user-friendly interface for pump selection further underscores Milestone's commitment to facilitating operational ease, allowing users to navigate through various specifications and diameters to meet their precise operational requisites.

As a testament to its unwavering dedication to customer-centric support, Milestone extends a repertoire of world-class production slurry pump replacement spare parts. These components, available in a diverse array of materials such as metal, rubber, polyurethane, and ceramic, underscore Milestone's versatility as the supplier of choice for the discerning mining industry. This comprehensive offering ensures that customers have access to top-tier components, enhancing the longevity of their slurry pumps and optimizing overall operational efficiency.

Milestone's MAH series of horizontal slurry pumps epitomizes the convergence of cutting-edge technology, user-centric design philosophy, and an unyielding commitment to quality. This series not only adeptly addresses the multifaceted needs of the mining industry but also firmly establishes Milestone as the reliable partner, poised to elevate the productivity and profitability of its customers through unparalleled innovation and precision engineering.

At Milestone, we recognize the unique requirements of our clients. Our OEM customization services are tailored to meet specific project needs, allowing us to deliver pumps that excel in efficiency and reliability. From material selection to design intricacies, we work closely with our clients to create solutions that align seamlessly with their objectives.

Embracing cutting-edge technology, our manufacturing process incorporates the latest advancements in dredging pump engineering. This ensures that our products not only meet but exceed industry standards. Our commitment to innovation is a driving force behind our ability to adapt to evolving market demands.

Choose Milestone for unparalleled expertise, customized solutions, and a legacy of 15 years in the dredging pump manufacturing industry.

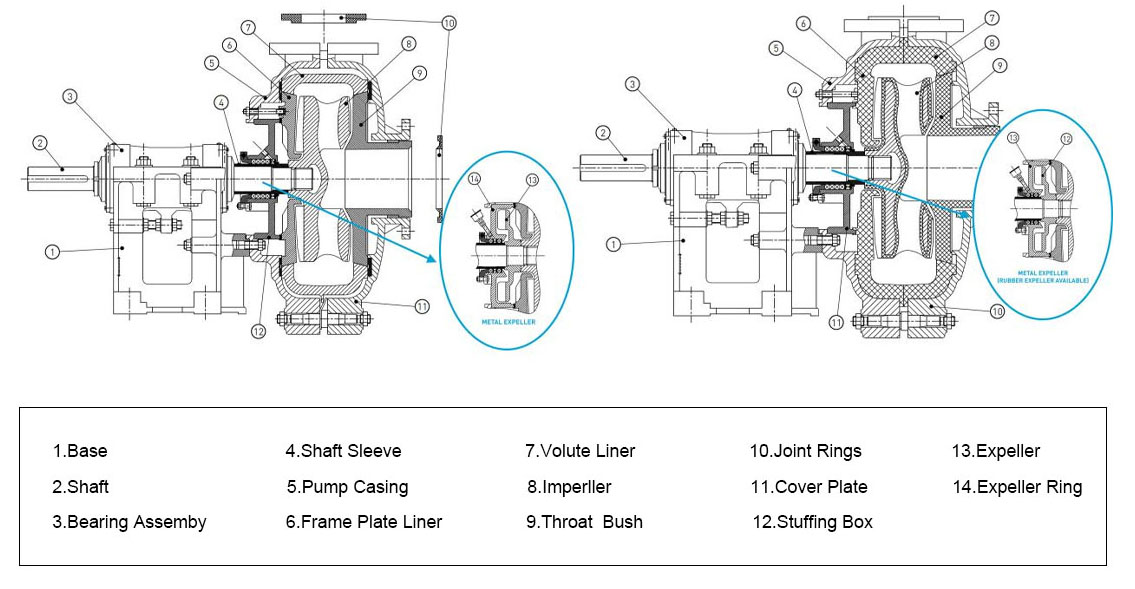

ASSEMBLY DRAWING

RELEVANT CONTENT

Frequently Asked Questions

Verderflex

-

What information is needed to offer a slurry pump?

The pump model or the below information.Liquid:

Capacity:_m3/hr

Head:_m

PH:

Specific of gravity:

Voltage:_ V,

Frequency: _hz -

What material pump can you supply?

A05, Natural rubber, ceramics, polyurethane, etc

-

Can you supply special or OEM parts?

Yes, please send me the detailed drawing or parts code to check

-

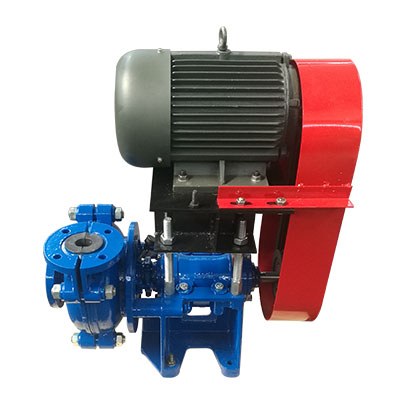

Do you only supply pumps? Could you supply driven equipment?

Yes, sure, the pumps could be coupled with motor and diesel engine, below brands for your reference Motor: WEG, SIMENS ABB, TECO, and Chinese brand diesel engines: Cummins, Deutz, Perkins, Volvo. Mitsubishi, Caterpillar, MTU.and Chinese brands

-

What is the delivery time?

10 days for normal pumps.