Submersible Slurry Pump

Submersible Slurry Pump

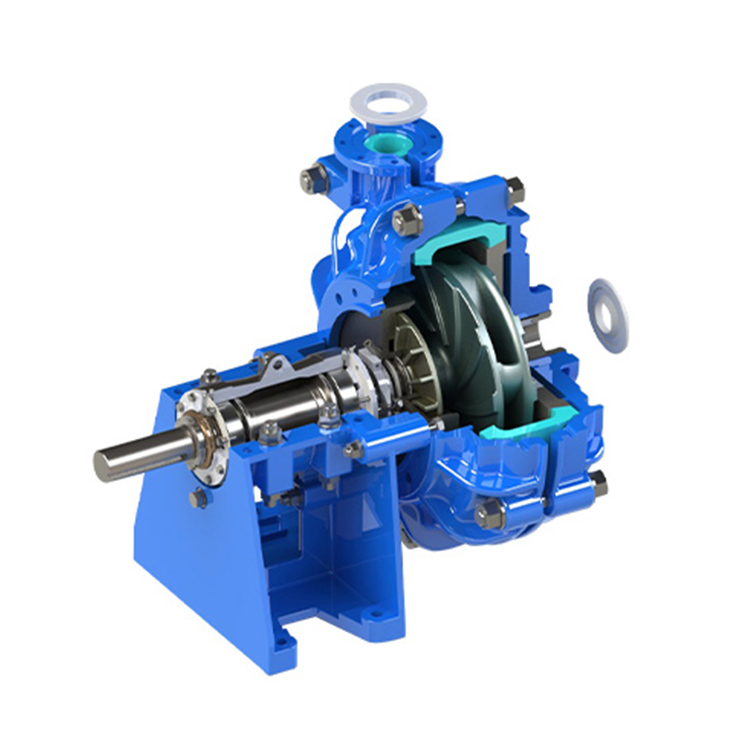

SS Submersible series are heavy-duty, submersible slurry pumps designed to handle a wide range of slurries sand abrasive particles in submersible applications in mining and industry. SS pumps feature a rugged construction using the highest quality materials to ensure reliable performance and excellent service life. The high-quality electric motors incorporate multiple protection features to detect the ingress of water or excessive temperatures to shut off the pump and prevent damage. Pumps can pass solids up to 60mm (2.4 inches) in diameter enabling them to transfer dense slurries with large abrasive particles.

Design Features

- Outlet: 3.15-15.7inch

- Flow rate: 25-2400m3/h

- Head: up to 64m

- Max. Power: up to 315kw

- Material: 27% were resistant Chrome

- Max. particle size: 12.5-60mm

- Speed: 1460rpm/ 980rpm

- Efficiency: 43-72%

The SS type submersible slurry pump is a water conservancy machine whose motor and water pump are coaxially integrated and submerged into the medium. The equipment has advanced structure, wide flow channel, strong sewage discharge capacity, excellent material selection and strong corrosion resistance. Suitable for transporting liquids containing solid particles such as sand, cinder, and tailings. It is mainly used for the removal and transportation of slurry liquids in metallurgy, mining, steel plants, thermal power plants and other enterprises. It is an ideal substitute for traditional slurry pumps.

The Milestone SS Series Submersible Slurry Pumps represent a cutting-edge solution for handling abrasive and high-density slurries, particularly in demanding industries such as mining, heavy manufacturing, civil construction, and municipal applications. With a primary focus on efficiency and durability, these electric submersible centrifugal pumps have been specifically designed to excel in the challenging task of pumping sand and slurries.

One of the standout features of the SS submersible slurry pumps is their robust construction, incorporating top-tier materials to ensure not only reliable performance but also an extended service life. The electric motors employed in these pumps are of high quality and come equipped with multiple protection features. These features act as safeguards, detecting potential issues such as water ingress or excessive temperatures. In the event of such conditions, the pump is automatically shut off, preventing damage and ensuring the longevity of the equipment.

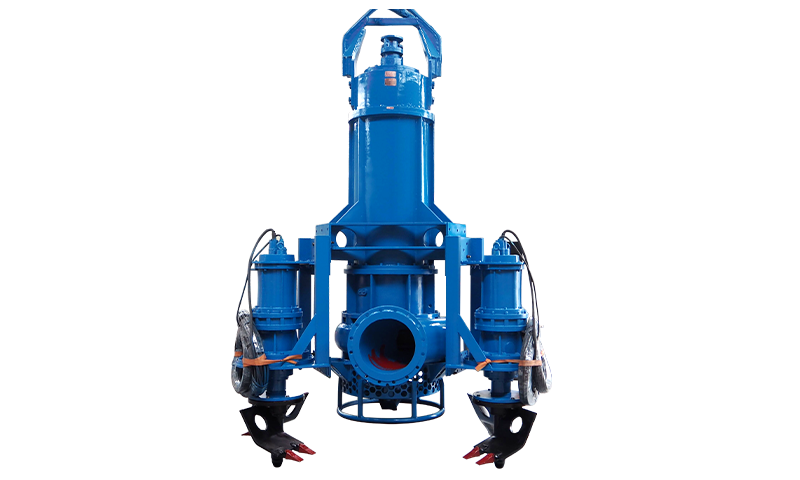

Dredging stands out as a prominent application for these pumps, encompassing a wide array of scenarios such as the dredging of rivers, harbors, dams, canals, lakes, and lagoons. The versatility of the SS dredging sand pump becomes evident in its ability to efficiently handle the pumping of solids mixed with water, effectively addressing challenges associated with dredging tasks. Notably, the pump's capability to control turbidity during dredging operations sets it apart, demonstrating its adaptability to varying environmental conditions.

SS sand dredging pump is designed and manufactured by absorbing foreign advanced technology. The use of high-tech wear-resistant materials greatly extends the life of the equipment and reduces the frequency of maintenance. In addition to the main impeller, a set of stirring impellers are added to the bottom of the water pump, which can spray the precipitated sludge into a swirling flow, allowing the water pump to achieve high-concentration transportation without auxiliary devices. The unique sealing device can effectively balance the pressure inside and outside the oil chamber, keeping the pressure at both ends of the mechanical seal balanced, ensuring the operational reliability of the mechanical seal to the greatest extent and greatly extending its service life. When necessary, the motor adopts protective measures such as overheating protection and water inlet detection protection, so that it can operate safely for a long time under harsh working conditions. At the same time, MST can also add protective measures such as motor anti-condensation bearing temperature measurement according to user requirements to meet users' use in different occasions. SS type submersible dredging pump has been favored by the majority of users since it was introduced to the domestic market.

The extensive range of SS dredging sand pump models, numbering 72 in total, accommodates diverse needs, with sizes ranging from 80mm to 400mm (3.15 - 16 inches) discharge. These pumps boast impressive flow rates, spanning from 23 to 2400 cubic meters per hour (100-10560 USGPM), and are capable of achieving heads up to 64 meters (210ft). Additionally, their ability to handle solids up to 60mm (2.4 inches) in diameter underscores their suitability for transferring dense slurry or sand laden with large abrasive particles.

The submersible slurry pump concept introduces several advantages compared to dry-mounted pumps. Not requiring a support structure minimizes the space needed for operation, making installation straightforward. The flood-proof nature of these pumps, due to their submersible design, ensures reliable operation even in challenging conditions. Moreover, the submerged operation contributes to a quieter working environment. The reduced time required for maintenance further enhances the appeal of these pumps.

A notable characteristic of the MST SS submersible dredging slurry pumps is their ability to operate across the complete pump curve, rather than being limited to a specific duty point. This versatility allows these pumps to find application in a multitude of scenarios within their range, breaking away from the traditional "one pump - one application" paradigm. In essence, the SS Series Submersible Slurry Pumps from Milestone exemplify a comprehensive and adaptable solution for efficiently handling abrasive slurries in diverse industrial and municipal settings.

Compared with ordinary slurry pumps, SS submersible slurry pump has the following characteristics:

- It is not limited by the suction stroke, has high slag suction efficiency and more thorough desilting.

- No need to equip auxiliary vacuum pump, lower investment.

- No auxiliary stirring or devices are required, making the operation simpler.

- There is no need to build complex ground protection and fixing devices when the motor is embedded underwater, which is simple and convenient.

- The stirring impeller is in direct contact with the deposition surface, and the concentration is controlled by the depth of penetration, so the concentration can be controlled more freely.

- The slurry pump is directly embedded in the underwater work, without noise and vibration, and the site is cleaner.

The submersible electric mixer is developed to improve the suction concentration of the slurry pump. It is suitable for different fields such as mine tailings, steel plants, power plants, slag discharge, seaport sand extraction, river sand extraction, river dredging, water conservancy project sewage treatment, etc. It is more efficient to use with SS submersible slurry pump.

In addition, the hydraulic wear-resistant slurry pumps and heavy-duty submersible dredging pumps supplied by MST are suitable for various series of small, medium-sized and large excavators such as 120, 150, 220, 240, 300, 330, 360, etc., where there is a lot of water and silt. . When the sediment is too thin and the bucket is inconvenient to dig, remove the bucket and connect it to a hydraulic mortar pump for efficient, high-concentration extraction. The hydraulic slurry pump is matched with the hydraulic slurry pump to achieve long-distance transportation. Greatly improve work efficiency. It can also be equipped with a hydraulic station to work in harsh environments, where excavators cannot effectively excavate due to too much water, long-distance transportation of mud and mortar, insufficient power supply, and frequent site changes. It has a wide range of applications.

Quality is the cornerstone of our manufacturing philosophy. Rigorous testing procedures are integrated into every stage of production to guarantee the durability and performance of our dredging pumps. Milestone takes pride in delivering products that withstand the most challenging operational conditions.

While rooted in China, Milestone has a global footprint. Our products have gained recognition and trust in international markets, a testament to the reliability and effectiveness of our dredging pump solutions.

Choose Milestone for unparalleled expertise, customized solutions, and a legacy of 15 years in the dredging pump manufacturing industry.

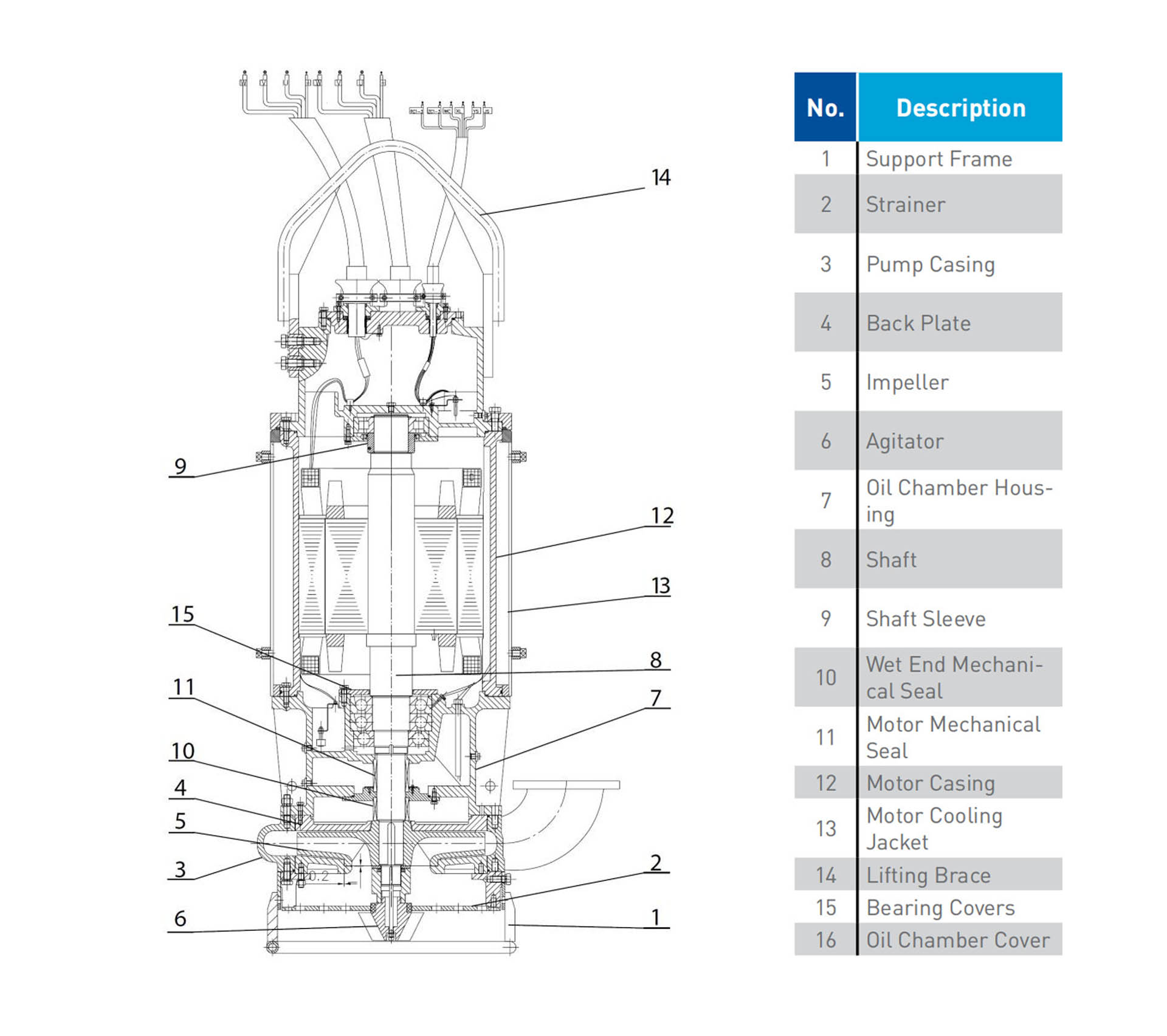

ASSEMBLY DRAWING

RELEVANT CONTENT

Frequently Asked Questions

Verderflex

-

What information is needed to offer a slurry pump?

The pump model or the below information.Liquid:

Capacity:_m3/hr

Head:_m

PH:

Specific of gravity:

Voltage:_ V,

Frequency: _hz -

What material pump can you supply?

A05, Natural rubber, ceramics, polyurethane, etc

-

Can you supply special or OEM parts?

Yes, please send me the detailed drawing or parts code to check

-

Do you only supply pumps? Could you supply driven equipment?

Yes, sure, the pumps could be coupled with motor and diesel engine, below brands for your reference Motor: WEG, SIMENS ABB, TECO, and Chinese brand diesel engines: Cummins, Deutz, Perkins, Volvo. Mitsubishi, Caterpillar, MTU.and Chinese brands

-

What is the delivery time?

What is the delivery time?