Horizontal Multistage Pump

Multistage High Head Pump

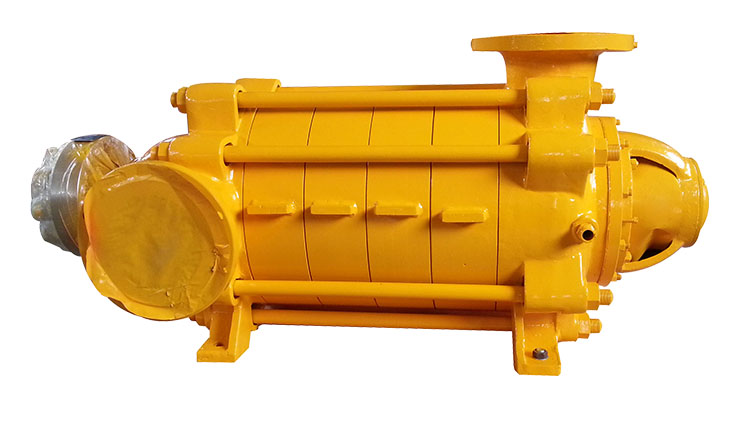

D serial pump is multistage centrifugal pump The serial pump is multistage section centrifugal pump, the excellent hydraulic models are high-efficiency, energy-saving, and have wide performance range, operate safely & steadily, have low noise long life, and installing & repairing are very convenient, etc. It can deliver heat water, oil, corrosive or wearable medium by changing the material seal or add cooling system.Type D pump can deliver water without solid particles or liquid whose chemical and physical features are similar to water and temperature is ≤80℃, it is suitable for delivering water in mines and urban water projects, etc.Type DG pump can deliver clean water without solid particles or liquid which chemical and physical features are similar to water, and temperature is < 105℃, it is suitable for delivering boiler feed water or heat waterType DM pump can deliver neuter mineral water with solid particles percent< 1.5% (solid Dia. < 05mm)and other similar sewage, the temperature of the liquid is ≤80℃, it is suitable for steel works, mines cities projects, etc.

Design Features

- Outlet: 65 - 200mm

- Flow rate: 3.75 - 840m3/h

- Head: 19 - 680m

- Max. Power: up to 315kw

- Speed: 1450-2900rpm

- Efficiency: up to 82%

- Operating Temperature: -10℃-110℃

- Casing Pressure(max): 30bar(60bar)

Multistage pumps play a crucial role in various industrial applications, particularly in scenarios where high pressure and efficient fluid transport are paramount. One notable application is the use of multistage wearable centrifugal mine water pumps, designed to handle clear water and neutral liquids with solid particles of up to 1.5% and granularity less than 0.5mm. These pumps find extensive use in mining operations, factories, and urban settings for water supply and drainage.

Multistage pumps play a crucial role in various industrial applications, particularly in scenarios where high pressure and efficient fluid transport are paramount. One notable application is the use of multistage wearable centrifugal mine water pumps, designed to handle clear water and neutral liquids with solid particles of up to 1.5% and granularity less than 0.5mm. These pumps find extensive use in mining operations, factories, and urban settings for water supply and drainage.

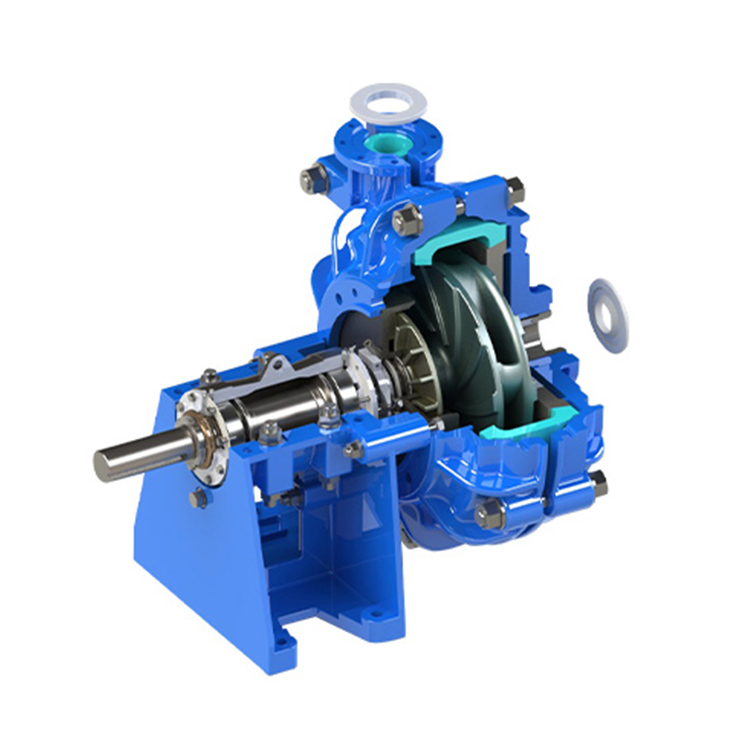

The design of a multistage pump involves incorporating two or more impellers, which can be of different types, such as low NPSH suction impellers, double suction impellers, or a combination of centrifugal first stage and side channel stage impellers. This versatility allows for a more tailored approach to various hydraulic requirements. Additionally, the pump's ability to accommodate different impeller types and trim them as needed provides flexibility in meeting specific duty points without compromise.

Compared to high-pressure duty pumps, the centrifugal multistage pump, despite being more complex and costly, offers distinct advantages. Its hydraulic efficiency and reliability are often superior, thanks to the precise control over duty points achievable through the addition or adjustment of impellers. This precision in meeting the Best Efficiency Point (BEP) contributes to the pump's overall efficiency and reliability in operation.

One notable feature of multistage pumps is the possibility of configuring them with an interstage bleed-off. This proves beneficial when multiple duty points are required, allowing for more versatile applications.

Moreover, the ability to run a multistage pump at a lower speed compared to a single-stage centrifugal pump can offer efficiency advantages, and the quieter operation addresses the growing concern for noise pollution in today's world. Even a small decrease in decibels represents a significant reduction in perceived noise, making multistage pumps a favorable choice in noise-sensitive environments.

Moreover, the ability to run a multistage pump at a lower speed compared to a single-stage centrifugal pump can offer efficiency advantages, and the quieter operation addresses the growing concern for noise pollution in today's world. Even a small decrease in decibels represents a significant reduction in perceived noise, making multistage pumps a favorable choice in noise-sensitive environments.

In situations where safety is a top priority, such as in coal mines, explosion-proof motor types are recommended for multistage pumps. This ensures compliance with safety standards and regulations while maintaining reliable and efficient pumping operations in potentially hazardous environments.

The centrifugal multistage pump stands out as a versatile, efficient, and reliable solution for high-pressure fluid transport in diverse industrial settings. Its adaptability, precision in meeting duty points, and potential for quiet operation make it a preferred choice in scenarios where hydraulic performance is critical.

The centrifugal multistage pump stands out as a versatile, efficient, and reliable solution for high-pressure fluid transport in diverse industrial settings. Its adaptability, precision in meeting duty points, and potential for quiet operation make it a preferred choice in scenarios where hydraulic performance is critical.

Recognizing the importance of environmental sustainability, we are dedicated to producing dredging pumps that minimize ecological impact. Our eco-friendly practices and adherence to international environmental standards underscore our commitment to a greener future.

Customer satisfaction is at the core of our business ethos. We prioritize open communication, timely delivery, and post-sales support, ensuring a seamless experience for our clients throughout the entire product lifecycle.

Choose Milestone for unparalleled expertise, customized solutions, and a legacy of 15 years in the dredging pump manufacturing industry.

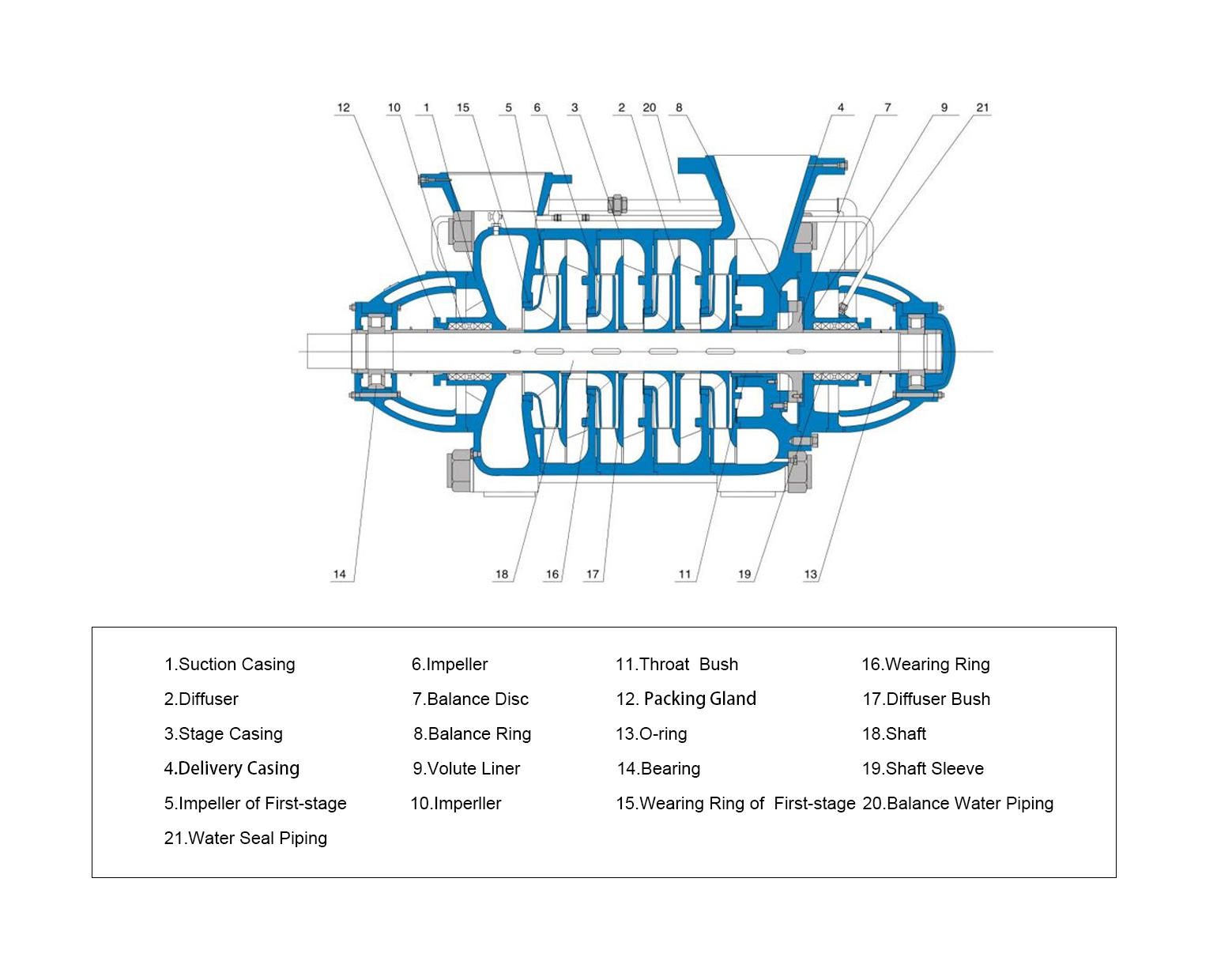

D series centrifugal multistage pump construction

D series water pump is a segmented multi-stage centrifugal pump, supported by foundations, and the suction section, middle section and discharge section are connected into one body by tightening bolts.

Has the following advantages:

1. Impellers, guide vanes and other flow-passing components are optimized and designed using CFD flow field analysis technology with high efficiency.

2. The static seal between the suction section, middle section and discharge section of the pump adopts metal surface seal and "O" ring double seal, and the pump shaft seal adopts High-performance ramie packing or mechanical seal, safe and reliable.

3. The pump type spectrum is wide, and the large flow pump is the leading technology in China.

4. The rotor adopts two static and dynamic balancing processes to strictly control the beating of the rotor. The pump operates stably and has small vibration.

5.The bearing adopts bushing installation structure and enlarged design, which is easy to disassemble and assemble, has strong bearing capacity and long service life.

6.The 6-axes are made of high-quality carbon steel or alloy steel that has undergone multiple heat treatment processes, resulting in high stiffness and good stability.

7.Adopting a unique shoulder positioning structure, the impeller positioning is more reliable and the operation is safe.

The D type centrifugal multistage pump has the suction section flange to the right when viewed from the coupling end; the discharge section flange is upward; the motor is arranged at the suction end. The material of the suction section, middle section, discharge section, guide vane and impeller is cast iron; the material of the shaft and sleeve is 45 steel or 40Cr; the material of the balance ring and sleeve is 3Cr13; the balance plate is 2Cr13; it is sealed with packing. Viewed from the coupling end toward the pump, the pump rotates clockwise.

The MD type centrifugal multistage pump has the suction section flange facing to the right when viewed from the coupling end; the discharge section flange faces upward; the motor is arranged at the suction end. The material of the suction section and the middle section is cast iron; the material of the discharge section, guide vane, and impeller is ductile iron; the material of the shaft and sleeve is 45 steel or 40Cr; the material of the sealing ring is stainless steel or copper alloy; the material of the balance ring and sleeve is 3Cr13; the balance plate It is 2Cr13; sealed with packing. Viewed from the coupling end toward the pump, the pump rotates clockwise.

ASSEMBLY DRAWING

RELEVANT CONTENT

Frequently Asked Questions

Verderflex

-

What information is needed to offer a slurry pump?

The pump model or the below information.Liquid:

Capacity:_m3/hr

Head:_m

PH:

Specific of gravity:

Voltage:_ V,

Frequency: _hz -

What material pump can you supply?

A05, Natural rubber, ceramics, polyurethane, etc

-

Can you supply special or OEM parts?

Yes, please send me the detailed drawing or parts code to check

-

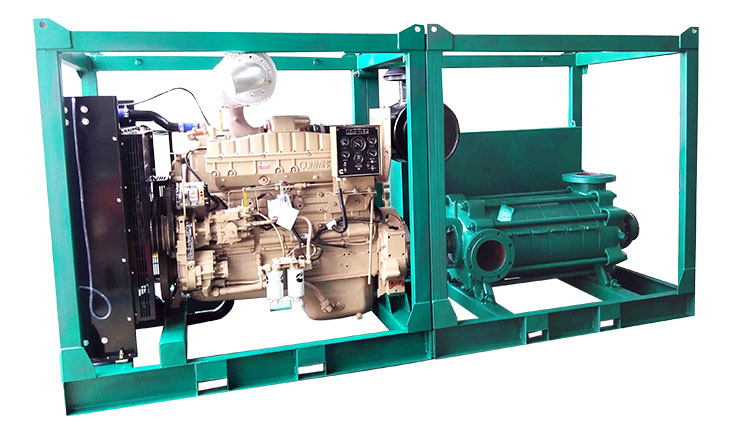

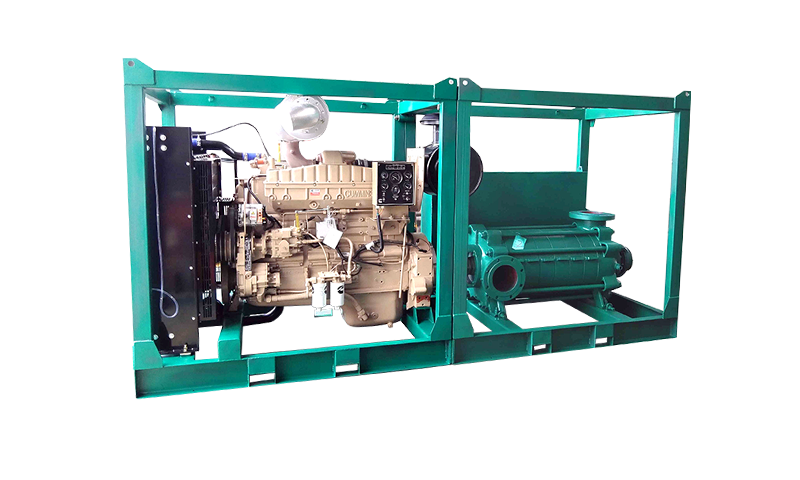

Do you only supply pumps? Could you supply driven equipment?

Yes, sure, the pumps could be coupled with motor and diesel engine, below brands for your reference Motor: WEG, SIMENS ABB, TECO, and Chinese brand diesel engines: Cummins, Deutz, Perkins, Volvo. Mitsubishi, Caterpillar, MTU.and Chinese brands

-

What is the delivery time?

10 days for normal pumps.