Z Horizontal Self Priming Pump

Self Priming Pump

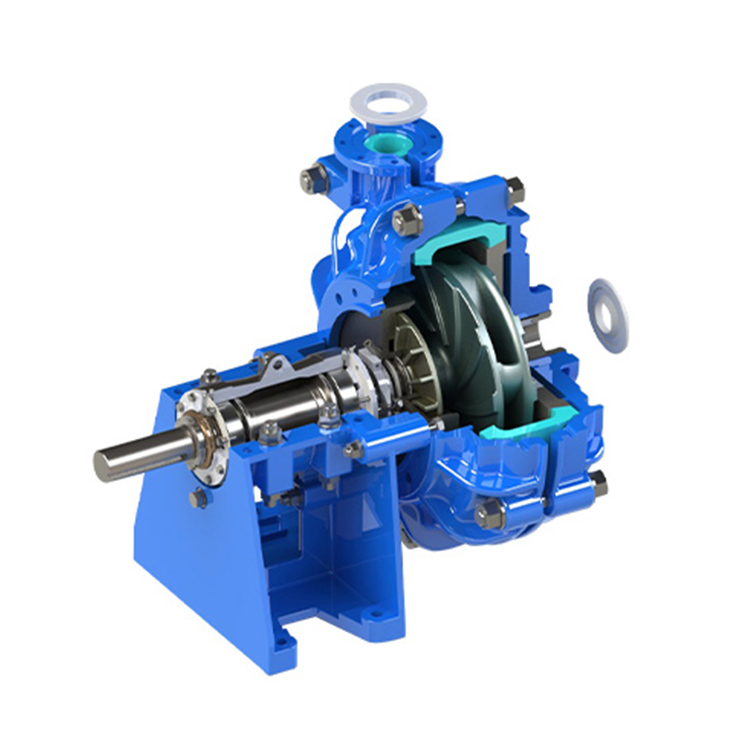

Z series self-priming pump is an energy-saving pump designed with ISO international standards and developed through absorbing and improving the related technical data both domestically and abroad and belongs to self-priming centrifugal pump and uses the mechanical seal of a ceramic ring to resist an

Design Features

- Outlet: 25 - 300mm

- Flow rate: up to 800m3/h

- Head: up to 80m

- Speed: up to 2900rpm

- Efficiency: up to 200%

- Operating Temperature: 200℃

Z Horizontal Self Priming Pump is an energy-saving pump designed with ISO international standards and developed through absorbing and improving the related technical data both domestically and abroad and belongs to self-priming centrifugal pump and uses the mechanical seal of a ceramic ring to resist any sandy liquid from going into the sealing face, preventing it from getting scratched. This pump holds the advantages of a compact structure, easy operation, stable movement, easy maintenance, high efficiency, long pipeline and only a certain amount of leading liquid is required to be filled into the pump before work, improves the work condition while simplifying the pipeline system.

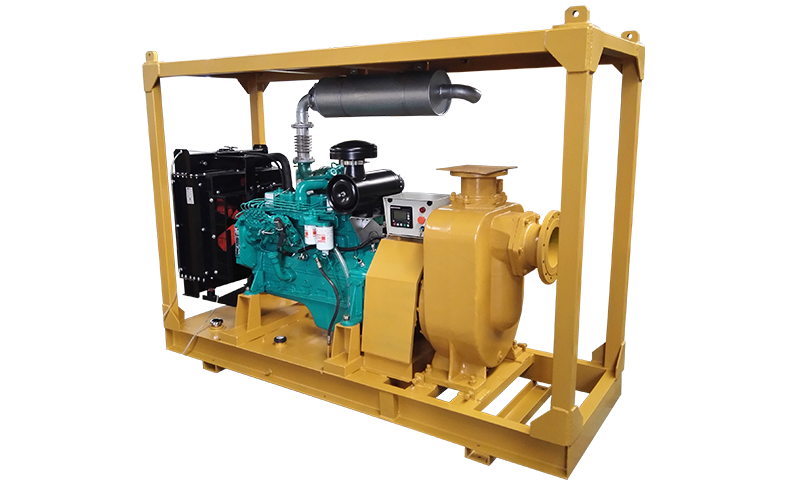

Centrifugal self priming pump can be equipped with either Y series common motor or YB series explosion-proof one upon the different surroundings of use.

Z Horizontal Self Priming Pump casing consists of a suck-in room, a liquid storing room, a scrolling room, a liquid back hole, an air-liquid separating room, etc., and holds an axially liquid back structure. After the pump is normally started, the impeller sucks in the all liquid inside of the suck-in room and the air inside of the pipeline and gets them completely mixed inside of it, then, under the action of the centrifugal force, the liquid, carrying the air flows towards the outer edge of the scroll room and, on the outer edge of the impeller, a white foam band of a certain thickness and a quickly rotating liquid ring are formed. The air-liquid mixture gets into the air-liquid separating room through the expanding pipe and, as the flow rate is abruptly lowered thereafter, the lighter air is separated from the mixture and rises through the vomit port of the pump casing and is exhausted therefrom. The liquid with the air-off returns to the liquid storage room and gets into the impeller again through the liquid back hole, where it is mixed again with the air sucked in from the suck-in pipeline and, under the action of the quickly rotating impeller, flows towards the outer edge of the impeller again, along with the repeated process, the air in the suck-in pipeline is continually reduced till being sucked up, the self-suction process ends and the pump gets into normal work. This unique exhaust capacity makes the pump able to transport the air-contained liquid without a foot valve mounted and of a good cabin cleaning function when used on an oil ship. There is a cooling room on the bottom of the bearing body with some pumps and, when the bearing body's temperature rise is over 70℃ with the bearing heated, the cooling liquid can be injected in through any one of the cooling liquid unions in the cooling room for cycled cooling. The sealing mechanism inside of the Z Horizontal Self Priming Pump used to prevent the liquid from leaking from the high-pressure area to the low one is the front and rear seal rings, the front ring is mounted on the pump casing, and the rear one is on the bearing body. When the seal ring gets worn out to a certain extent after a long time of work on the pump thus affecting both its efficiency and self-suction properties, it should be replaced.

ASSEMBLY DRAWING

RELEVANT CONTENT

Frequently Asked Questions

Verderflex

-

What information is needed to offer a Z Horizontal Self Priming Pump?

The pump model or the below information.

Liquid:

Capacity:_m3/hr

Head:_m

PH:

Voltage:_ V,

Frequency: _hz -

How could I do if I cannot supply the above information?

Please send us your requirements as detailed as possible. We will recommend pumps to you.

-

What material pump can you supply?

Cast iron, Cast steel, SS304, SS316L etc

-

Do you only pumps? Could you supply driven equipment?

Yes, sure, the pumps could be coupled with motor and diesel engine, below brands for your reference Motor: WEG, SIMENS ABB, TECO, and Chinese brand diesel engines: Cummins, Deutz, Perkins, Volvo. Mitsubishi, Caterpillar, MTU.and Chinese brands

-

What is the delivery time?

10 days for normal pumps.